U.S. Hosiery and Sock Market. Analysis And Forecast to 2030

Get instant access to more than 2 million reports, dashboards, and datasets on the IndexBox Platform.

View PricingDemand for Hosiery in the U.S. Expects a Colorful Ascend

The hosiery market of today abounds in numerous types of this accessory: textured, footless, printed, opaque, and leggings just to name a few. A current fashion trend is shape and structure perfection.

As in other industries, technology has been playing an essential role in the tights business. Mechanical knitting machinery has been replaced by more compact and sophisticated electronic machines capable of more production volumes in a shorter period of time.

In the U.S., vendors are using laser and ultrasonic technology to enhance the accuracy of fabric cutting. The laser technology also reduces the time for changing the cutting heads in different fabrics, thus boosting productivity. Ultrasonic technology helps in cutting all fabrics with sealed edges to prevent their fraying. With advances in technology, wastage is reduced, allowing for sustainable utilization of resources and improved profit margins for vendors.

Changing lifestyles have also greatly influenced the tights industry. The rapidly expanding teen and young adult market is now filled with a plethora of brand-new looks and an incredibly wide array of colors every season.

In order to win their market share, tights manufacturers are betting on competitive pricing policies, including multipack promotions for throwaway prices. New collections never fail to sate customers' yearning for variety, ranging from natural and classic styles to more bold glitzy and animal print looks.

High-fashion trends give the manufacturers freedom to experiment with designs and fabrics, fomented by the customers that are willing to try out new unconventional patterns and quirky designs. It makes sense, then, for companies to avoid holding onto a trend for too long, and, instead, simply try to keep up with volatile tastes and the rapid shift of consumer demand.

At present, leggings are all the rage, especially opaque colorful ones. Leggings are generally more long-lasting than tights and are now considered more convenient and practical. Tights are being readily used for dance, exercise or as a ready-to-wear fashion accessory. Color is a key determinant in the sales of solid alternative legwear, especially for tights. Opaque leggings in rainbow patterns are dominant in high-fashion brands and accessories.

Despite the fact that low labor costs and production expenditures keep most of the manufacturing of tights and leggings overseas, it is still too early to completely write off the U.S. domestic hosiery manufacturing industry. Walmart, for instance, recently announced that it is expanding its "Made in the USA" program by investing $X million in existing production facilities to produce No Nonsense leggings, tights and socks. Also in 2014, Renfro Corporation invested $X million in U.S. based production capacity for sock manufacturing.

China was the main supplier of hosiery and socks into the U.S., increasing its share from X% in 2007 to X% in 2014 of total U.S. imports. The fastest growing suppliers were El Salvador (+X% per year) and China (+X% per year) in total imports from 2007 to 2014.

In 2014, the main destinations of U.S. hosiery and sock exports were Canada (X%), El Salvador (X%) and Vietnam (X%). The share exported to Vietnam increased (+X percentage points), while the share sent to Mexico illustrated negative dynamics (-X percentage points). The shares of the other countries remained relatively stable throughout the analyzed period.

Join Us at HANNOVER MESSE 2024

Don’t miss your chance to connect with us directly. Schedule a personal meeting to dive deeper into how solutions.

Hall 002, Stand C10. 22 - 26 April 2024 | Hannover, Germany

This report provides an in-depth analysis of the hosiery and sock market in the U.S.. Within it, you will discover the latest data on market trends and opportunities by country, consumption, production and price developments, as well as the global trade (imports and exports). The forecast exhibits the market prospects through 2030.

Product coverage:

- NAICS 315110 - Hosiery and sock mills

Companies mentioned:

- Renfro Corporation

- Spanx, Thorlo

- Kayser-Roth Corporation

- Acme - McCrary Corporation

- Slane Hosiery Mills

- Harriss & Covington Hosiery Mills

- Gildan USA

- Fox River Mills

- Crescent Sock Company

- Wells Hosiery Mills

- For Bare Feet

- Mayo Knitting Mill

- Universal Hosiery

- Gildan Delaware

- Trimfit

- Cooper Hosiery Mills

- Carolina Hosiery Mills

- Star America

- Leg Resource

- Bossong Hosiery Mills

- Twin City Knitting Company

- Nester Hosiery

- Huffman Finishing Company

- Candor Hosiery Mills

- Lemco Mills

- Roka Apparel Products

- US Test Company 150

- Smith Hosiery

- Holt Hosiery Mills

Country coverage:

- United States

Data coverage:

- Market volume and value

- Per Capita consumption

- Forecast of the market dynamics in the medium term

- Trade (exports and imports) in the U.S.

- Export and import prices

- Market trends, drivers and restraints

- Key market players and their profiles

Reasons to buy this report:

- Take advantage of the latest data

- Find deeper insights into current market developments

- Discover vital success factors affecting the market

This report is designed for manufacturers, distributors, importers, and wholesalers, as well as for investors, consultants and advisors.

In this report, you can find information that helps you to make informed decisions on the following issues:

- How to diversify your business and benefit from new market opportunities

- How to load your idle production capacity

- How to boost your sales on overseas markets

- How to increase your profit margins

- How to make your supply chain more sustainable

- How to reduce your production and supply chain costs

- How to outsource production to other countries

- How to prepare your business for global expansion

While doing this research, we combine the accumulated expertise of our analysts and the capabilities of artificial intelligence. The AI-based platform, developed by our data scientists, constitutes the key working tool for business analysts, empowering them to discover deep insights and ideas from the marketing data.

-

1. INTRODUCTION

Making Data-Driven Decisions to Grow Your Business

- REPORT DESCRIPTION

- RESEARCH METHODOLOGY AND AI PLATFORM

- DATA-DRIVEN DECISIONS FOR YOUR BUSINESS

- GLOSSARY AND SPECIFIC TERMS

-

2. EXECUTIVE SUMMARY

A Quick Overview of Market Performance

- KEY FINDINGS

- MARKET TRENDS This Chapter is Available Only for the Professional Edition PRO

-

3. MARKET OVERVIEW

Understanding the Current State of The Market and Its Prospects

- MARKET SIZE

- MARKET STRUCTURE

- TRADE BALANCE

- PER CAPITA CONSUMPTION

- MARKET FORECAST TO 2030

-

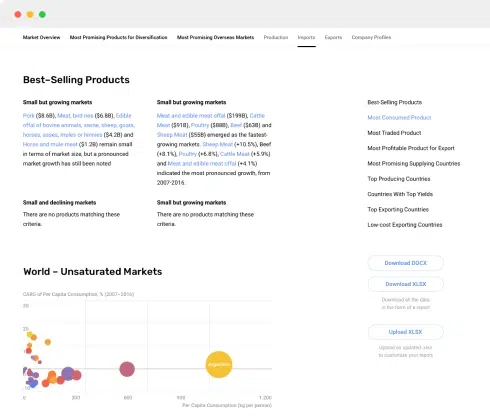

4. MOST PROMISING PRODUCT

Finding New Products to Diversify Your Business

This Chapter is Available Only for the Professional Edition PRO- TOP PRODUCTS TO DIVERSIFY YOUR BUSINESS

- BEST-SELLING PRODUCTS

- MOST CONSUMED PRODUCT

- MOST TRADED PRODUCT

- MOST PROFITABLE PRODUCT FOR EXPORT

-

5. MOST PROMISING SUPPLYING COUNTRIES

Choosing the Best Countries to Establish Your Sustainable Supply Chain

This Chapter is Available Only for the Professional Edition PRO- TOP COUNTRIES TO SOURCE YOUR PRODUCT

- TOP PRODUCING COUNTRIES

- TOP EXPORTING COUNTRIES

- LOW-COST EXPORTING COUNTRIES

-

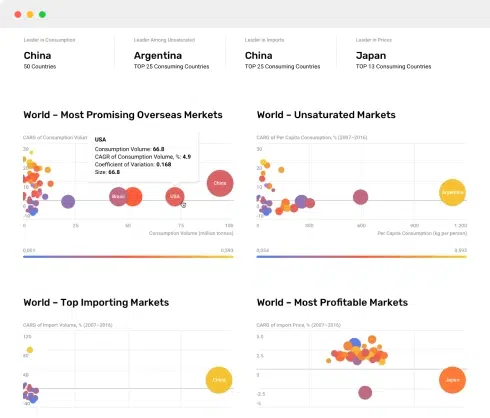

6. MOST PROMISING OVERSEAS MARKETS

Choosing the Best Countries to Boost Your Exports

This Chapter is Available Only for the Professional Edition PRO- TOP OVERSEAS MARKETS FOR EXPORTING YOUR PRODUCT

- TOP CONSUMING MARKETS

- UNSATURATED MARKETS

- TOP IMPORTING MARKETS

- MOST PROFITABLE MARKETS

7. PRODUCTION

The Latest Trends and Insights into The Industry

- PRODUCTION VOLUME AND VALUE

8. IMPORTS

The Largest Import Supplying Countries

- IMPORTS FROM 2012–2023

- IMPORTS BY COUNTRY

- IMPORT PRICES BY COUNTRY

9. EXPORTS

The Largest Destinations for Exports

- EXPORTS FROM 2012–2023

- EXPORTS BY COUNTRY

- EXPORT PRICES BY COUNTRY

-

10. PROFILES OF MAJOR PRODUCERS

The Largest Producers on The Market and Their Profiles

This Chapter is Available Only for the Professional Edition PRO -

LIST OF TABLES

- Key Findings In 2023

- Market Volume, In Physical Terms, 2012–2023

- Market Value, 2012–2023

- Per Capita Consumption In 2012-2023

- Imports, In Physical Terms, By Country, 2012–2023

- Imports, In Value Terms, By Country, 2012–2023

- Import Prices, By Country Of Origin, 2012–2023

- Exports, In Physical Terms, By Country, 2012–2023

- Exports, In Value Terms, By Country, 2012–2023

- Export Prices, By Country Of Destination, 2012–2023

-

LIST OF FIGURES

- Market Volume, In Physical Terms, 2012–2023

- Market Value, 2012–2023

- Market Structure – Domestic Supply vs. Imports, In Physical Terms, 2012-2023

- Market Structure – Domestic Supply vs. Imports, In Value Terms, 2012-2023

- Trade Balance, In Physical Terms, 2012-2023

- Trade Balance, In Value Terms, 2012-2023

- Per Capita Consumption, 2012-2023

- Market Volume Forecast to 2030

- Market Value Forecast to 2030

- Products: Market Size And Growth, By Type

- Products: Average Per Capita Consumption, By Type

- Products: Exports And Growth, By Type

- Products: Export Prices And Growth, By Type

- Production Volume And Growth

- Exports And Growth

- Export Prices And Growth

- Market Size And Growth

- Per Capita Consumption

- Imports And Growth

- Import Prices

- Production, In Physical Terms, 2012–2023

- Production, In Value Terms, 2012–2023

- Imports, In Physical Terms, 2012–2023

- Imports, In Value Terms, 2012–2023

- Imports, In Physical Terms, By Country, 2023

- Imports, In Physical Terms, By Country, 2012–2023

- Imports, In Value Terms, By Country, 2012–2023

- Import Prices, By Country Of Origin, 2012–2023

- Exports, In Physical Terms, 2012–2023

- Exports, In Value Terms, 2012–2023

- Exports, In Physical Terms, By Country, 2023

- Exports, In Physical Terms, By Country, 2012–2023

- Exports, In Value Terms, By Country, 2012–2023

- Export Prices, By Country Of Destination, 2012–2023